Blends and repackaging

Optimise your value chain with Procudan Blends

Procudan Blends is our service for manufacturing companies that want to optimise and streamline their production processes.

We offer both blends and repackaging:

- Blends: We supply ready-made and pre-mixes that can be incorporated directly into your production to ensure a smooth process.

- Repackaging: We repackage raw materials or finished products in larger or smaller packaging to suit your production flow.

We place great emphasis on flexibility and quality in all our deliveries, and production is carried out exclusively in state-of-the-art facilities.

All our blends and repackaging can be customised to your exact requirements, increasing capacity and flexibility in both production and stock management.

With Procudan Blends, you get

Full security

Eliminate the risk of contamination with CIP cleaning in production

Stable environment

Consistently stable temperature and humidity in production

One total price

Avoid unforeseen costs for transport, storage and logistics

.jpg&AlternativeImage=/Images/missing_image.jpg)

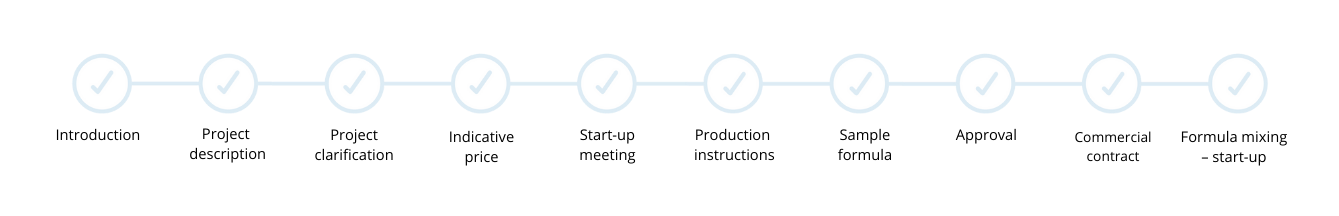

Security in ten steps

We follow a clear and structured process to ensure the best solution for your needs.

Before starting production, we go through ten crucial steps with you, carefully assessing all relevant key parameters. This gives you a safe and efficient experience when you entrust us with blending and repackaging tasks.

Read the latest insights

Procudan Blends allows the blending of powders and liquid solutions and repackaging into other packaging

Powders

Mixing of ingredients to produce e.g. ice cream mix or baking mix.

Can also be used to make premix products such as milk powder or proteins.

Liquid solutions

Solutions of ingredients like salt, sweeteners or additives.

Ingredients can also be retapped.

Repackaging

Ingredients or blends are repackaged to packets in the right size and material.

From 0.5 gram to big bags.

There are several advantages to letting us handle parts of the production process

Lower production risk

Economic benefit

Improved working environment

Opportunities to add value

Lower production risk

- You get delivery and weighing according to your needs

- You get the same product quality all year round as we use complete climate control

- You are protected against foreign objects as we use a detailed production instruction and perform risk analyses

- You are protected against allergen contamination as we clean with CIP

Economic benefit

- You get lower inventory ties as we can deliver just-in-time to you

- You can avoid or postpone expensive investments in inventory or production

- You minimise the costs of mis-mixing and thus waste in production

Improved working environment

- You avoid errors as you receive batch-weighted units

- You avoid heavy lifting by using smaller packaging units

- You can outsource dusty processes to us

- You reduce manual tasks for production workers

Opportunities to add value

- You free up space and capacity for other things in your production

- You gain the flexibility to create new products with existing equipment

- You optimise warehousing and logistics with variable stock pull

/Ismageriet 8E0A5143 high ress_1500_400_2.jpg&AlternativeImage=/Images/missing_image.jpg)

Read about blends for Ismageriet

We start with your current situation

Flexible solutions according to your requirements

If you are already using an external supplier, you could also benefit from a customised Procudan Blends setup.

You should be aware that:

- Our blending facilities ensure the highest possible food safety and quality standards. They are structured to use CIP cleaning processes to prevent contamination, as well as a very low impact transport system that is gentle to your ingredients, also during mixing.

- Our production equipment is installed in halls with air conditioning to ensure stability of both temperature and humidity. This avoids seasonal challenges like static electricity and clumping.

- All workflows are documented and follow fixed procedures in accordance with the ten-step production instructions that we agree with you before mixing begins.

- We provide one total price, which, in addition to the price of the blend or repackaging, also includes what we agree upon on transport, storage and logistics.

- It is possible to merge the solution with, for example, other forms of streamlining, such as sourcing of ingredients and packaging, as well as one of our customised logistics and warehousing solutions.

- Our high standards for quality, documentation and food safety are a common thread through every aspect of our business and mean that you can safely entrust us to take care of your product. Take a look at our certifications.

Greater security and capacity for your production

Inviting suppliers all the way into your production process is a big step. However, moving parts of your production off site gives you greater capacity and more flexibility.

You should be aware that:

- Not only can Procudan Blends help you to solve specific challenges that you are facing right now, they can also help you to create opportunities and room to develop in the longer term.

- An external blending partner allows you to achieve a simpler and more focused workflow in your own production. This means having to deal with fewer potential uncertainties, while also making it easier for staff to perform their tasks. All this allows you to safeguard and ensure your production flow.

- Perhaps you could create a working environment where less heavy lifting is required and where new employees take less time to train. The simpler process will also be able to help you to avoid mistakes, while maintaining quality standards and achieving the best product uniformity.

Let us take care of sourcing ingredients and packaging, as well as customised logistics and warehousing solutions

Ready for large-scale production

At our PilotBlends facilities, we carry out trial productions where both the recipe and the process are tested and adjusted. This ensures that the blend has the desired composition and quality.

The aim is to ensure that both the product and the production process are working optimally before we move on to the first commercial large-scale production.

PilotBlends is usually part of step seven: Sample formula in our structured process Security in ten steps.